CORRUGATED TUBES

A corrugated tube heat exchanger offers significant improvements both in heat transfer and energy efficiency.When the fluid flows through a corrugated tube, vortexes are created inside and outside the tube. These vortexes increase the amount of fluid in contact with the tube surface, thus improving heat transfer compared to smooth tubes.

Another advantage of the corrugated tube is that its special shape produces turbulences that have a strong self-cleaning effect and thus prevent fouling inside the heat exchanger.

In addition, corrugated tubes do not require expansion joints for thermal stress because they can withstand high temperature changes.

Corrugated tubes are ideal for heat exchangers used in systems of the food, naval, chemical, pharmaceutical and refrigeration sectors.

In addition, corrugated tubes do not require expansion joints for thermal stress because they can withstand high temperature changes.

Corrugated tubes are ideal for heat exchangers used in systems of the food, naval, chemical, pharmaceutical and refrigeration sectors.

Materials

- Stainless steel (austenitic)

- Nickel alloys

Production Capacity (approximate)

| Tube Diameter | Wall Thickness | Corrugation Pitch |

|---|---|---|

| 10 / 70 mm 0.39 / 2.75 in |

0.5 / 1.65 mm 0.019 / 0.064 in |

From 10 to 25 mm from 0.39 to 0.98 in |

| Corrugation Depth | Tube Length |

|---|---|

| Max. 1 mm 0.039 in |

Max. 22000 mm 866 in |

Packaging

We suggest packaging in bundles for corrugated tubes.

Dimensional Checks

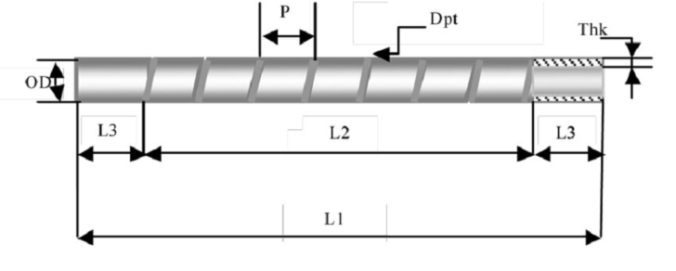

OD = Outside diameter of the tube

Thk = Wall thickness

P = Corrugation pitch

Dpt = Corrugation depth

L1 = Total length

L2 = Length of corrugated section

L3 = Length of plain ends

Thk = Wall thickness

P = Corrugation pitch

Dpt = Corrugation depth

L1 = Total length

L2 = Length of corrugated section

L3 = Length of plain ends

Locations

Registered office

Via Beato Alberto Marvelli, 39

47039 Savignano Sul Rubicone (FC) - Italy

VAT number and fiscal code: 11491870967

Via Beato Alberto Marvelli, 39

47039 Savignano Sul Rubicone (FC) - Italy

VAT number and fiscal code: 11491870967

Operational headquarters

Via Ansaldo, 5/7

47122 Forlì (FC) - Italy

Via Ansaldo, 5/7

47122 Forlì (FC) - Italy

Write us for information